Selecting durable UV-resistant marine ropes is essential for safety and efficiency in harsh maritime environments. Standard ropes deteriorate quickly due to saltwater corrosion, weather conditions, and UV radiation, prompting the need for advanced coatings. These protective barriers prevent premature degradation, ensuring the longevity of boat ropes for critical tasks like navigation, anchoring, and towing. With superior strength and flexibility, UV-resistant marine ropes are valuable assets, reducing replacement costs and downtime in both commercial shipping and recreational boating. Future innovations include eco-friendly coatings and customized solutions tailored to specific marine applications.

“Explore the innovative world of marine rope technology with a focus on UV-resistant coatings. This article delves into the critical aspects of understanding unique marine rope requirements and highlights the transformative power of UV-resistant coating technology.

We examine its benefits for various boat rope applications, from enhanced durability to improved safety. Furthermore, we anticipate future trends, ensuring mariners stay ahead with advanced marine rope solutions. Unravel the secrets behind this game-changing technology for an optimal boating experience.”

- Understanding Marine Rope Requirements

- The Role of UV-Resistant Coating Technology

- Benefits and Applications of UV-Resistant Marine Rope

- Future Trends in Marine Rope Coating

Understanding Marine Rope Requirements

In the dynamic marine industry, understanding the unique challenges and requirements of marine ropes is paramount for ensuring safety and performance at sea. Marine ropes, subjected to relentless exposure from harsh weather conditions, corrosive saltwater, and constant motion, demand exceptional durability and strength. Additionally, they must withstand the damaging effects of ultraviolet (UV) radiation from the sun, which can cause rapid degradation and loss of integrity over time. Thus, selecting a suitable rope for marine applications involves careful consideration of factors such as tensile strength, flexibility, resistance to wear and tear, and most importantly, UV-resistance to prevent premature failure.

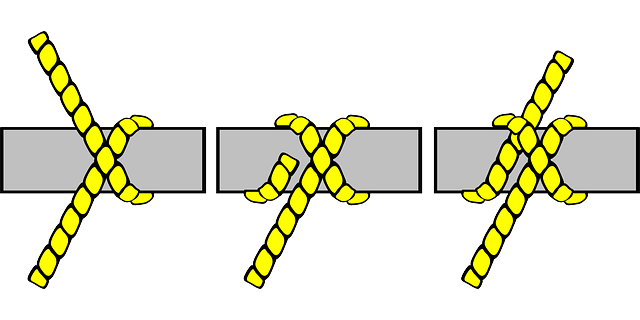

Boat ropes, designed to support various maritime activities from sailing to towing, require specialized coatings that can enhance their performance and longevity. The need for UV-resistant marine rope is evident, as standard untreated ropes can weaken and lose their effectiveness within a few months of continuous outdoor use. By incorporating advanced coating technologies, manufacturers address these concerns, offering boat owners and operators a reliable solution that ensures the safety and efficiency of their vessels.

The Role of UV-Resistant Coating Technology

The marine environment poses unique challenges for rope due to its corrosive and harsh conditions. This is where UV-resistant coating technology plays a pivotal role in protecting marine ropes from early degradation. UV radiation, present in sunlight, can significantly accelerate the aging process of natural and synthetic rubbers used in boat ropes, leading to reduced strength and flexibility over time.

UV-resistant coatings form an protective barrier, shielding the rope from harmful UV rays. These advanced coatings are designed to withstand extreme marine conditions, ensuring the longevity of boat ropes. By preventing the breakdown caused by UV exposure, these technologies preserve the integrity of marine ropes, maintaining their critical functions for navigation, anchoring, and towing operations. This results in safer boating experiences and reduced maintenance costs for vessel owners.

Benefits and Applications of UV-Resistant Marine Rope

UV-resistant marine ropes offer a plethora of benefits for boat owners and marine industry professionals. One of its key advantages is enhanced durability; the UV coating protects the rope from the sun’s harmful rays, preventing degradation and fraying often caused by prolonged exposure to ultraviolet light. This results in a longer lifespan for the rope, reducing replacement costs and minimizing downtime for vessels.

These ropes find extensive applications in various marine settings, from commercial shipping to recreational boating. In maritime environments, where UV radiation is intense, UV-resistant boat ropes are indispensable. They are commonly used for mooring lines, anchor chains, and winching systems due to their superior strength and flexibility. The coating also provides excellent resistance to chemicals often found at sea, making these ropes suitable for tasks involving exposure to salt water and other marine substances.

Future Trends in Marine Rope Coating

The future of marine rope coating looks promising with a growing focus on advanced materials and technologies. One of the key trends is the development of UV-resistant coatings for boat ropes, which are designed to withstand the harsh conditions of prolonged sun exposure. These innovative coatings not only enhance the lifespan of the ropes but also maintain their strength and flexibility over time.

Additionally, researchers and manufacturers are exploring eco-friendly options, such as biodegradable materials and water-based formulations. This shift towards sustainability is crucial in keeping up with environmental regulations. The industry is also witnessing an increase in customized coating solutions tailored to specific marine applications, ensuring optimal performance for various types of boat ropes.

Rope coating technology, particularly UV-resistant varieties, plays a pivotal role in enhancing the lifespan and performance of marine ropes. By safeguarding against the damaging effects of sunlight and water, UV-resistant marine rope offers boaters and maritime professionals a reliable, durable solution for diverse applications. As innovation continues to drive advancements in marine rope coatings, we can expect even greater efficiency, strength, and sustainability in the future, further revolutionizing navigation and aquatic endeavors.