UV-resistant marine ropes are essential for climates with high sunlight exposure, ensuring longevity and performance for various boating needs, including mooring lines and tow ropes. Natural ropes like hemp or jute offer rot resistance but absorb moisture, while synthetic ropes made from polyester or nylon excel in UV protection and strength. High-quality UV-resistant marine ropes, designed specifically for maritime use, provide superior durability and resistance to harsh sea conditions, maintaining integrity for extended periods.

In the world of maritime operations, understanding the construction and selection of suitable ropes is paramount for safety and efficiency. This article delves into the intricate details of marine rope construction, focusing on UV-resistant varieties crucial for enduring harsh coastal conditions. We explore various types, from natural to synthetic fibers, highlighting their applications and advantages. The manufacturing process, design features, installation tips, and maintenance routines are dissected to ensure readers can navigate this essential component effectively.

- Types of Marine Rope and Their Uses

- – Overview of different marine rope categories

- – Applications based on material (e.g., natural vs synthetic) and construction

- Design Features for UV-Resistant Marine Rope

Types of Marine Rope and Their Uses

Marine ropes come in various types, each designed for specific tasks and conditions. One critical attribute to consider when choosing a marine rope is its UV resistance. UV-resistant marine ropes are essential for boats operating in sunny climates or exposed to prolonged sunlight as these ropes are built to withstand the damaging effects of ultraviolet radiation, ensuring they retain their strength and flexibility over time.

Boat ropes serve multiple purposes, from mooring and anchoring to pulling and towing. For instance, high-quality UV-resistant marine rope is ideal for mooring lines as it can handle constant exposure to water and sunlight without degrading. In contrast, tow ropes require superior tensile strength and durability to safely move vessels, especially in rough waters. Different marine ropes are engineered with specific performance characteristics in mind, catering to the diverse needs of boating applications.

– Overview of different marine rope categories

Marine ropes are categorised based on their composition, construction, and intended use to ensure optimal performance in diverse marine environments. One key distinction is between natural and synthetic ropes. Natural ropes, like those made from hemp or jute, have been used for centuries due to their flexibility and strength. However, they require regular maintenance to prevent rot and mildew. Synthetic ropes, on the other hand, offer superior resistance to water absorption, UV rays, and extreme weather conditions, making them a popular choice for modern marine applications, including boating and sailing.

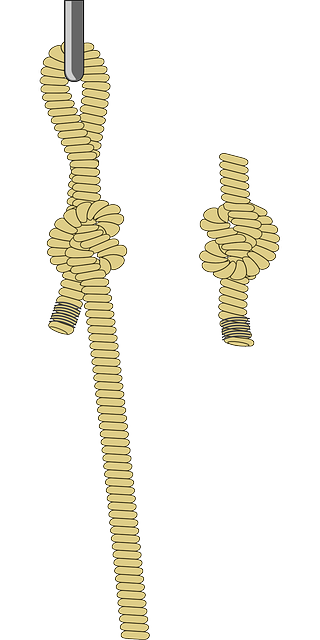

UV-resistant marine rope, in particular, is designed with added chemicals or coatings that protect against sun damage, prolonging its lifespan. Boat ropes come in various types, each suited to specific tasks. For instance, mooring lines need to be sturdy yet flexible, while anchor lines require immense strength to handle heavy weights. Understanding these categories and their attributes is crucial when selecting marine rope to ensure safety, efficiency, and the longevity of vessels.

– Applications based on material (e.g., natural vs synthetic) and construction

When it comes to marine applications, the choice between natural and synthetic ropes is pivotal, each offering distinct advantages tailored to specific needs. Natural ropes, traditionally made from materials like hemp or jute, possess exceptional durability and rot resistance, making them ideal for mooring and anchor lines where longevity is paramount. However, they can be prone to absorption of moisture, which may affect handling and strength over time. On the other hand, synthetic ropes, commonly constructed from polyester or nylon, excel in UV-resistant properties, ensuring their integrity remains intact even under prolonged sun exposure—a crucial factor for boat ropes enduring the harsh marine environment.

The construction process also plays a significant role in determining the suitability of a rope for marine use. Strands woven tightly together create robust ropes capable of withstanding immense tension without compromising strength or elasticity. Twisted ropes, another common construction method, offer enhanced flexibility and resistance to kinking, making them popular choices for various marine tasks. Moreover, core-infused synthetic ropes incorporate an additional layer of protection, enhancing their overall performance in challenging marine conditions, thus catering to the diverse requirements of maritime activities.

Design Features for UV-Resistant Marine Rope

Selecting the right marine rope, such as a durable UV-resistant boat rope, is paramount for ensuring safety and efficiency in maritime operations. Understanding the diverse types of marine ropes available, their construction features, and specific uses enables users to make informed choices tailored to their needs. By prioritizing high-quality materials and thoughtful design elements, including UV resistance, boaters and mariners can safeguard their equipment while navigating various aquatic environments.