When choosing a marine rope for your vessel, it's critical to select one with robust UV resistance to ensure longevity and safety under seafaring conditions. Polyester marine ropes, enhanced with UV inhibitors, are highly recommended due to their superior durability against environmental stressors like saltwater and sun exposure. These ropes maintain their mechanical properties over time, making them ideal for critical applications such as mooring lines and sheet lines. Nylon ropes, also available with UV protection, offer flexibility for less permanent or frequently adjusted lines. For applications demanding exceptional UV resistance and durability, polyester is the superior choice. It outperforms nylon in resisting degradation from UV radiation and environmental factors. Polypropylene fibers are another excellent option, providing unparalleled resilience against ultraviolet light, ensuring the rope retains its strength and flexibility over an extended period. These ropes are versatile, suitable for various marine uses including rigging sailboats, anchoring larger vessels, and more, thanks to their ease of handling and cost-effectiveness. Ultimately, the selection between polyester, nylon, or polypropylene should be based on the specific application requirements and environmental factors to ensure optimal performance and reliability at sea. For both recreational and commercial maritime applications, investing in a high-quality UV-Resistant marine rope is essential for maintaining vessel integrity and safety.

When venturing across the vast expanse of the ocean, the reliance on robust and resilient marine ropes is paramount. This article delves into the critical aspects of selecting the appropriate UV-Resistant marine rope, a term that encompasses boat ropes designed to withstand the rigors of maritime environments. We compare the durability and performance of popular synthetic options such as polyester and nylon in mooring lines and lashing applications. Additionally, we explore the enduring qualities of high-performance marine ropes like polypropylene, highlighting their suitability for various tasks. With a focus on practicality and longevity, this guide assists in choosing the right rope based on specific application needs and environmental factors to ensure safety and long-term durability at sea.

- Understanding the Importance of UV-Resistant marine rope for Seafaring Safety and Durability

- Comparing Synthetic Boat Ropes: Polyester vs. Nylon for Mooring Lines and Lashing

- The Longevity of High-Performance Marine Ropes: A Look at Polypropylene and Its Applications

- The Ultimate Guide to Selecting the Right UV-Resistant marine rope Based on Application Needs and Environmental Factors

Understanding the Importance of UV-Resistant marine rope for Seafaring Safety and Durability

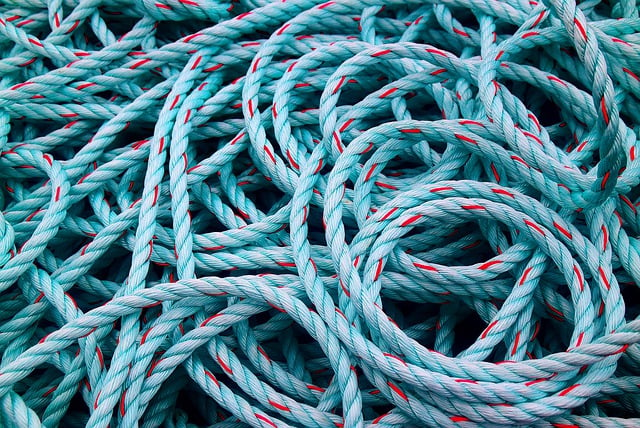

When selecting the appropriate marine rope for seafaring applications, the importance of UV-resistance cannot be overstated. Exposure to the sun’s ultraviolet rays is a primary cause of degradation in synthetic ropes used on boats. Over time, UV radiation can weaken and discolor boat ropes, compromising their structural integrity and leading to potential safety hazards. Boat rope manufacturers have innovated with UV-resistant materials to mitigate these risks. These advanced marine ropes are engineered to withstand the harsh maritime environment, ensuring longevity and maintaining their mechanical properties even after prolonged sun exposure. The inclusion of UV inhibitors within the rope construction slows down the photodegradation process, which is critical for the durability and reliability of the rope under constant solar radiation.

Incorporating a UV-resistant marine rope into your vessel’s systems significantly contributes to its longevity and safety at sea. Unlike traditional ropes that may become brittle and prone to failure after prolonged sun exposure, these advanced ropes maintain their flexibility and strength. This is particularly important for critical applications such as mooring lines, sheet lines, or any other lines under constant tension. By choosing marine rope with high UV resistance, seafarers can rest assured that their equipment will perform consistently, regardless of the weather conditions or the length of time spent on the water.

Comparing Synthetic Boat Ropes: Polyester vs. Nylon for Mooring Lines and Lashing

When selecting a marine rope for mooring lines and lashing, it is crucial to consider the durability and resilience of the material against environmental factors, particularly UV exposure. Both polyester and nylon are popular choices for UV-resistant boat ropes due to their ability to withstand the harsh conditions encountered at sea. Polyester, known for its high tensile strength and excellent resistance to abrasion, provides a reliable option for mooring lines. It maintains its strength over time and is less likely to degrade from exposure to saltwater and sunlight compared to other synthetic fibers. This makes polyester an ideal choice for applications where longevity and consistent performance are paramount.

Nylon, on the other hand, offers a balance of flexibility and strength, making it a versatile material for lashing. It has a history of use in marine applications due to its resistance to water and chemicals. While nylon is generally more affected by UV rays than polyester, advancements in rope manufacturing have led to the development of UV-resistant marine ropes made from nylon that can last longer in the sun. Both materials are durable and have their unique advantages; however, when considering a boat rope for mooring or lashing, one must weigh the specific needs of the application against the properties of each material. Polyester’s superiority in UV resistance and abrasion resistance may outweigh nylon’s flexibility in situations where longevity is a priority, while nylon’s adaptability might be more suitable for less permanent or frequently adjusted lines. Ultimately, the choice between polyester and nylon for a UV-resistant marine rope should be based on the specific requirements of the task at hand and the environmental conditions the rope will face.

The Longevity of High-Performance Marine Ropes: A Look at Polypropylene and Its Applications

Polypropylene fibers are a staple in the marine industry due to their remarkable resilience and durability under harsh marine conditions. These high-performance ropes, often labeled as UV-resistant marine rope, exhibit exceptional longevity, which is paramount for applications where reliability is non-negotiable. Exposure to the sun’s ultraviolet rays can degrade many materials over time, but polypropylene fibers are engineered to withstand such effects effectively, maintaining their strength and flexibility even after prolonged use. This UV resistance ensures that boat ropes made from polypropylene remain functional and aesthetically pleasing for an extended period, reducing the need for frequent replacements and minimizing maintenance demands.

The applications of UV-resistant marine rope are vast, ranging from rigging on sailboats to securing fenders on larger vessels. Polypropylene ropes are known for their lightweight properties, which make them an ideal choice for boating enthusiasts who prioritize ease of handling and maneuverability. Their ability to maintain a consistent level of performance in wet conditions further solidifies their status as a preferred material for marine applications. The longevity of these ropes translates to cost-effectiveness over time, as they provide consistent service without the frequent replacements often required by other, less durable materials. This makes them a wise investment for both recreational and commercial maritime endeavors.

The Ultimate Guide to Selecting the Right UV-Resistant Marine Rope Based on Application Needs and Environmental Factors

When selecting a UV-resistant marine rope for your maritime applications, it is imperative to consider both the intended application needs and the environmental factors that will influence the rope’s longevity and performance. Boat ropes are subjected to harsh conditions, including intense sunlight and saltwater exposure, which can degrade traditional fibers over time. To mitigate these challenges, ropes engineered with UV-resistant properties are a prudent choice. These ropes are specifically designed to resist the degrading effects of ultraviolet radiation, ensuring they maintain their strength and flexibility even after prolonged exposure.

For sailboats, dinghies, and other recreational vessels, ropes made from high-tenacity polyester fibers infused with UV inhibitors are often preferred due to their exceptional durability and resistance to water. These materials exhibit a low stretch characteristic, which is crucial for precise control and handling in dynamic sailing conditions. Alternatively, for larger commercial vessels or heavy-duty applications like towing and mooring, nylon ropes with advanced UV protection can be more suitable due to their greater elasticity and abrasion resistance. Regardless of the material chosen, always ensure that the rope’s construction aligns with the specific demands of your marine activity to guarantee safety and optimal performance at sea. Factors such as the rope’s diameter, tensile strength, and flexibility must be carefully weighed against the environmental conditions it will face, ensuring you select a UV-resistant marine rope that is fit for purpose.

In conclusion, selecting the appropriate UV-resistant marine rope is a critical decision for maritime activities, influencing both safety and durability over time. The comparison between synthetic options like polyester and nylon reveals that each material offers unique advantages for specific applications, with polypropylene emerging as a high-performance choice for certain tasks. Ultimately, boat owners and professionals must consider the environmental factors and their particular use case when selecting a rope to ensure optimal performance and longevity at sea. The right UV-resistant marine rope not only enhances the vessel’s functionality but also contributes to the overall safety of all onboard.