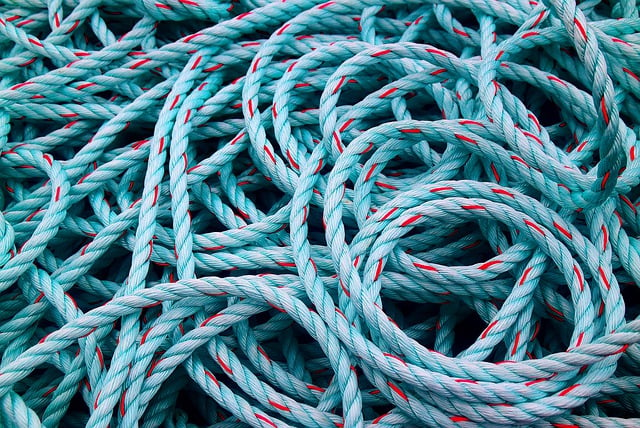

When selecting a UV-Resistant Marine Rope for your vessel, prioritize high-tenacity fibers like polyester due to their superior strength-to-diameter ratio, durability, and resistance to UV rays. A multi-filament core ensures flexibility and prevents kinks, while a braided outer layer offers enhanced abrasion and chafe resistance. The rope should be UV-resistant to protect against solar radiation, ensuring its longevity. For specific conditions like frequent submersion or use in brackish water, look for ropes with additional water-resistant treatments. Consider the diameter and flexibility tailored to your boat's needs, whether for mooring lines, fender tethers, or securing gear. Opt for ropes with certifications or manufacturer guarantees against UV degradation for tested and proven integrity in sunny environments. Both nylon and polyester have their benefits: nylon is elastic and resistant to abrasion and salty water but requires protection from UV light, while polyester is highly UV-resistant and stable across weather conditions with less stretch, ensuring consistent tension. The braiding pattern, like helical or Z-patterns, is crucial for durability, resistance to abrasion and water ingress, and maintaining the rope's strength and functionality over time. Ensure the diameter and breaking strength of the rope match your application's demands to guarantee safety and performance at sea. Investing in UV-resistant marine ropes extends their lifespan and ensures consistent performance under maritime conditions.

When navigating the vast expanses of the maritime world, reliability and safety are paramount. High-strength marine rope plays a critical role in this domain, serving as a linchpin for vessels and their operations. This article delves into the essential attributes of UV-resistant marine rope for boats, guiding you through material comparisons, braiding patterns, and maintenance practices to ensure your boat rope stands up to the elements and demands of seafaring. From understanding its importance to selecting the right composition and diameter, we’ll provide comprehensive insights to extend the lifespan of your marine rope and maintain optimal performance on the water.

- Understanding the Importance of High-Strength Marine Rope for Maritime Applications

- Key Factors to Consider When Selecting UV-Resistant Marine Rope for Boats

- Material Composition: Nylon vs. Polyester in High-Strength Marine Ropes

- The Role of Braiding Patterns in the Durability and Performance of Marine Rope

- Ensuring Adequate Rope Diameter and Breaking Strength for Your Maritime Needs

- Tips for Maintaining and Storing Your High-Strength Marine Rope to Extend Its Lifespan

Understanding the Importance of High-Strength Marine Rope for Maritime Applications

Key Factors to Consider When Selecting UV-Resistant Marine Rope for Boats

When selecting a high-strength marine rope that is resistant to UV rays for your boat, it’s crucial to consider several factors to ensure both safety and longevity. Firstly, the material of the rope should be of utmost importance. High-tenacity polyester fibers are often preferred for their superior strength-to-diameter ratio, durability, and resistance to UV radiation. These fibers maintain their integrity under constant exposure to sunlight, which can degrade other materials over time. Additionally, the core construction plays a significant role in the rope’s performance. A multi-filament core provides flexibility and reduces the chance of kinking, while braided constructions offer more resistance to abrasion and chafe. The outer sheathing should also be UV-resistant to protect the inner strands from solar radiation, ensuring the rope retains its properties even after extended use in direct sunlight.

Furthermore, consider the working environment of the rope. For instance, if the rope will frequently be submerged or used in brackish water, it’s advisable to select a marine rope with additional water-resistant treatments. The diameter and flexibility of the rope should also align with the boat’s specific applications, whether it’s for mooring, tethering fenders, or securing equipment. Always opt for marine ropes that come with certifications or manufacturer guarantees against degradation from UV exposure, as these have been rigorously tested and proven to perform well under such conditions. By carefully evaluating these factors, boat owners can ensure they choose a high-quality, UV-resistant marine rope that will endure the harsh marine environment and remain reliable for years to come.

Material Composition: Nylon vs. Polyester in High-Strength Marine Ropes

When selecting a high-strength marine rope for your maritime needs, understanding the material composition is paramount. Nylon and polyester are two commonly used materials in UV-resistant marine ropes, each with distinct advantages. Nylon, a synthetic polymer, has long been a staple in boat ropes due to its high tensile strength and elasticity. It excels in resisting abrasion and is highly resilient against salty water environments, which can be corrosive over time. Nylon’s ability to stretch and recover makes it ideal for applications where shock absorption is necessary. However, nylon is susceptible to UV degradation, necessitating regular maintenance and protection from prolonged sun exposure to maintain its strength and integrity.

In contrast, polyester marine ropes offer superior resistance to UV rays, making them an excellent choice for long-term outdoor use without the need for frequent treatments or coatings. Polyester’s inherent durability and stability in various weather conditions contribute to its reputation as a high-performance material in marine applications. It is less stretchy than nylon, providing consistent tension and load distribution. This characteristic makes polyester an ideal choice for applications where precision and control are critical, such as mooring lines or dinghy warps. Additionally, polyester’s resistance to water and mildew ensures that it remains strong and reliable even after extensive use in harsh marine environments. When choosing between nylon and polyester UV-resistant marine ropes, consider the specific requirements of your application, including environmental factors, the type of load the rope will bear, and your maintenance capabilities. Both materials have unique properties that can serve you well on the water, ensuring your vessel’s safety and functionality.

The Role of Braiding Patterns in the Durability and Performance of Marine Rope

When selecting a high-strength marine rope for nautical applications, the braiding pattern plays a pivotal role in determining the durability and performance of the rope under various conditions at sea. High-quality UV-resistant marine ropes, such as those used for boat rope applications, often feature sophisticated braiding designs that enhance their resistance to abrasion and wear. These patterns also facilitate better control and handling, which is crucial when maneuvering in challenging environments where the rope may be subjected to intense forces. The helical or Z-patterns are particularly favored due to their high tensile strength, which allows them to withstand significant loads while maintaining flexibility and elongation properties. Additionally, these patterns help prevent the ingress of water, which can degrade the material over time, especially when exposed to saltwater and the harmful effects of UV radiation. By incorporating fibers with inherent UV resistance, manufacturers ensure that the rope retains its strength, durability, and flexibility, even after prolonged exposure to the sun’s rays, thus extending its lifespan and ensuring optimal performance on boats and during marine activities. The choice of braiding pattern is therefore a critical factor in the overall integrity and longevity of marine ropes, contributing to their reliability and safety in diverse maritime conditions.

Ensuring Adequate Rope Diameter and Breaking Strength for Your Maritime Needs

When selecting a high-strength marine rope for your maritime endeavors, the rope’s diameter and breaking strength are pivotal factors to consider. A rope with an adequate diameter ensures not only its durability but also its efficiency in handling tasks of varying scales. For instance, heavier tasks may necessitate a thicker rope to distribute the load effectively across its strands, preventing potential breakage. The breaking strength, often specified in pounds or kilograms, is indicative of the maximum load the rope can bear before failure. It’s imperative to select a rope with a breaking strength that exceeds the expected loads encountered during your maritime activities to maintain safety at sea.

In the context of environmental resilience, UV-resistant marine ropes are paramount, especially when exposed to the harsh elements of the marine environment. The sun’s ultraviolet (UV) rays can degrade traditional fibers over time, leading to weakness and potential failure. To mitigate this, opt for ropes engineered with UV-resistant materials that ensure longevity and reliability even under prolonged exposure. This attribute not only safeguards the rope’s integrity but also extends its service life, which is a critical consideration for any boater or maritime professional. Quality boat rope, constructed with high tensile strength and incorporating UV resistance, will maintain its performance characteristics season after season, proving to be a sound investment in the safety and success of your maritime operations.

Tips for Maintaining and Storing Your High-Strength Marine Rope to Extend Its Lifespan

When selecting the right high-strength marine rope for your maritime tasks, such as boat rope, it’s crucial to consider the material composition, braiding patterns, and diameter to ensure safety and longevity. UV-resistant marine rope, specifically designed to withstand harsh marine environments, is an invaluable asset for seafarers and vessel owners. By adhering to maintenance and storage best practices, your marine rope will remain robust and reliable, ready to endure the demands of the sea. Invest in a UV-resistant marine rope that suits your needs, and you’ll safeguard your boat while navigating the waters with confidence.