UV-resistant marine ropes are essential for maritime applications due to their ability to endure harsh saltwater and UV conditions that degrade conventional ropes. These ropes, often made from high-performance synthetic fibers like polyester or nylon, are engineered with UV inhibitors and hydrolysis stabilizers to maintain their integrity and functionality. The protective sheath on these ropes ensures longevity and resists environmental factors, making them suitable for a variety of uses such as boat mooring, sail rigging, and heavy-duty tasks like towing and anchoring. Polyester marine ropes are preferred for their superior UV resistance, while nylon offers flexibility for mooring lines and fenders. Braided polyethylene ropes excel in resisting both UV light and chemical exposure for heavier applications. Proper maintenance includes regular inspection, freshwater rinsing to prevent corrosion, gentle cleaning, and storage in a dry, well-ventilated area, away from direct sunlight. Applying a specialized protectant further safeguards the rope's performance and extends its lifespan. This care ensures that your UV-resistant boat rope will continue to serve reliably for extended periods on the water.

UV-resistant marine ropes are indispensable for maritime activities, enhancing safety and performance on the water. This comprehensive guide delves into the critical role these ropes play in various maritime applications, from deck lines to rigging masts. We’ll explore their scientific composition, the materials that give them unparalleled durability against the harsh effects of ultraviolet light, and the different types available for diverse marine needs. Additionally, we’ll provide maintenance tips to ensure your boat rope maintains its integrity over time, ensuring it remains reliable under sail.

- Understanding the Importance of UV-Resistant Marine Rope in Maritime Applications

- Composition and Materials: The Science Behind UV-Resistant Marine Rope Durability

- Types of UV-Resistant Marine Ropes and Their Suitable Uses

- Maintenance and Care for Extending the Lifespan of Your UV-Resistant Boat Rope

Understanding the Importance of UV-Resistant Marine Rope in Maritime Applications

UV-resistant marine rope plays a pivotal role in maritime applications due to its unique properties that withstand the harsh conditions of a saltwater environment and prolonged exposure to ultraviolet radiation. Boat rope, commonly made from synthetic fibers such as polyester or nylon, is designed to resist degradation caused by the sun’s UV rays, which can significantly shorten the lifespan of traditional ropes. The durability of marine rope is not just a matter of longevity but also of safety and performance. In applications ranging from securing vessels to rigging sails, the integrity of the rope is paramount. It ensures that the boat remains safe and operational in all weather conditions, preventing potential accidents at sea. The resistance to UV light also minimizes the need for frequent replacements, reducing maintenance costs and downtime for both commercial and recreational vessels. When selecting marine rope, considering the specific UV-resistant properties can extend its lifespan, ensuring that it performs reliably over time, even in the most demanding maritime environments.

Composition and Materials: The Science Behind UV-Resistant Marine Rope Durability

The durability of UV-resistant marine ropes is primarily attributed to their sophisticated composition and the advanced materials used in their construction. These ropes, often utilized for boating applications where exposure to sunlight is inevitable, are engineered to withstand the harsh effects of ultraviolet radiation, which can otherwise lead to degradation and weakness over time. The core of a high-quality marine rope typically consists of polyester or nylon fibers, chosen for their strength and resistance to water. These core materials provide the initial structural integrity of the rope.

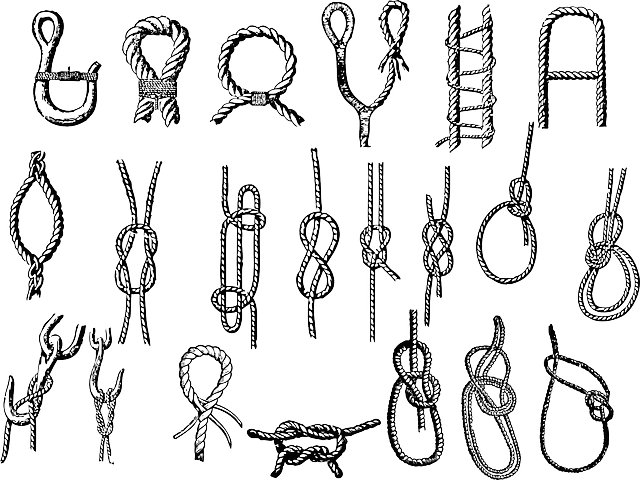

The outer sheath, which encases the core, is where the UV resistance comes into play. It is composed of yarns that have been specially treated with ultraviolet inhibitors (UVI) and sometimes hydrolysis stabilizers to protect against environmental factors such as saltwater, sunlight, and abrasion. This treatment, often a combination of chemical additives and protective coatings, prevents the breakdown of the polymer chains that would otherwise occur due to UV radiation. The result is a marine rope that maintains its mechanical properties—such as tensile strength, elasticity, and knot retention—even after prolonged exposure to the elements. This ensures that boat ropes remain functional and reliable, safeguarding both marine vessels and the tasks they perform.

Types of UV-Resistant Marine Ropes and Their Suitable Uses

When it comes to marine applications, the durability and performance of rope materials are paramount, especially under the relentless exposure of sunlight and saltwater. UV-Resistant Marine Rope stands out as a superior choice for various maritime needs due to its enhanced resistance against the degrading effects of ultraviolet radiation. This type of rope is typically constructed with high-tenacity yarns that are coated or impregnated with UV inhibitors, ensuring longevity and maintaining strength even after prolonged exposure to the sun’s rays.

There are several types of UV-Resistant Marine Rope catering to different requirements on a vessel. Polyester ropes, often referred to as ‘boat rope,’ are a popular choice for their high resistance to UV radiation and abrasion. They are ideal for use in sheet lines and halyards where aesthetics and long-term performance are crucial. Another variant is the nylon marine rope, which, while slightly more absorbent than polyester, also benefits from UV inhibitors and is commonly used for mooring lines and fenders due to its flexibility and strength. For heavy-duty applications such as towing lines or anchor ropes, braided polyethylene ropes are often the material of choice, offering remarkable resistance to both UV light and chemical attacks. Each type of rope has its unique advantages and is selected based on the specific demands of the task at hand, ensuring that whether it’s for recreational or commercial use, your marine rope will endure the harshest maritime environments with minimal maintenance required.

Maintenance and Care for Extending the Lifespan of Your UV-Resistant Boat Rope

Maintaining and caring for your UV-resistant marine rope is crucial for ensuring its longevity and performance on the water. Regular inspection is the first step in prolonging the life of your boat rope. Look for signs of wear, such as fraying or discoloration, especially where the rope experiences the most stress, like at pulleys or around winches. Cleaning the rope with freshwater after each use, particularly if it has been exposed to saltwater, helps prevent corrosion and salt buildup, which can degrade the material over time. Use a soft-bristled brush to gently scrub any dirt or debris from the rope’s surface without damaging the fibers.

To further extend the lifespan of your UV-resistant marine rope, it’s important to employ proper storage practices. After use, allow the rope to dry completely in a well-ventilated area away from direct sunlight. This not only prevents mold and mildew growth but also reduces the risk of the UV rays degrading the rope’s protective coating. When storing for extended periods, coil the rope loosely and hang it to avoid kinks or permanent bends that can weaken the material over time. Additionally, applying a marine rope protectant specifically designed for UV resistance can enhance the shielding against ultraviolet radiation, ensuring your boat rope remains supple and durable for many seasons to come.

When selecting a UV-resistant marine rope for your maritime needs, understanding its composition and materials is key. As detailed in this guide, these ropes are engineered to withstand the harsh conditions of the marine environment, particularly the damaging effects of ultraviolet (UV) radiation. The diversity of UV-resistant boat ropes available ensures there’s an optimal choice for every application, from dock lines to sailboat rigging. Regular maintenance and proper care can further extend their lifespan, making them a cost-effective and durable solution. With the insights provided in this article on the importance, composition, types, and care of UV-resistant marine ropes, you are now well-equipped to make informed decisions that will keep your maritime operations running smoothly and safely for years to come.